What Salt Is Produced When Sodium Hydroxide Reacts With Sulfuric Acid?

The chemical reaction between sodium hydroxide and sulfuric acid is a common laboratory experiment that produces a salt known as sodium sulfate. This salt is widely used in various industrial applications, including detergents, paper production, glass manufacturing, and textiles. The production of sodium sulfate has gained significant attention due to its importance in agriculture and environmental impact.

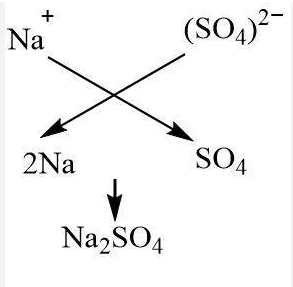

Sodium sulfate is an ionic compound that consists of positively charged sodium ions (Na+) and negatively charged sulfate ions (SO4-2). The reaction between sodium hydroxide and sulfuric acid involves the exchange of ions to form water and sodium sulfate. This reaction can be represented by the following equation:

NaOH + H2SO4 → Na2SO4 + 2H2O

In this article, we will delve into the properties of sodium sulfate, its industrial applications, production methods, importance in agriculture, environmental impact, safety precautions during handling and storage of this salt. Additionally, we will compare it with other salts produced from different chemical reactions. Finally, we will explore further research and development opportunities for this ubiquitous compound.

Explanation of the Chemical Reaction between Sodium Hydroxide and Sulfuric Acid

The chemical reaction between sodium hydroxide and sulfuric acid results in the formation of a salt, which can be visualized as small white crystals.

This reaction mechanism involves the exchange of hydrogen ions between the two compounds.

The stoichiometry of the reaction requires one molecule of sodium hydroxide to react with one molecule of sulfuric acid, resulting in the formation of sodium sulfate and water.

The process is exothermic, meaning that it releases heat energy during the course of the reaction.

This chemical equation is represented as NaOH + H2SO4 → Na2SO4 + 2H2O.

It is essential to maintain a balanced ratio between these two compounds for optimal yield during this process.

Properties of Sodium Sulfate

One of the notable characteristics of sodium sulfate is its ability to form colorless, odorless crystals. These crystals have a specific crystal structure and solubility properties that make them useful in various industrial applications.

Sodium sulfate has a high solubility in water, which makes it an excellent drying agent for organic materials such as fabrics and paper products.

Additionally, the crystal structure of sodium sulfate allows it to be used as a flux in metallurgy, aiding in the removal of impurities from metal ores during smelting processes.

Overall, the unique properties of sodium sulfate make it a versatile chemical compound with various industrial uses.

Industrial Applications of Sodium Sulfate

Sodium sulfate, also known as Glauber’s salt, has various industrial applications.

It is commonly used in the production of detergents, where it acts as a filler and a bulking agent.

In paper production, sodium sulfate is used to improve the strength and durability of paper fibers.

In textiles, it is used as a leveling agent to ensure uniform dyeing of fabrics.

Additionally, sodium sulfate finds use in glass manufacturing processes and pharmaceutical formulations.

Detergents

Detergents, commonly used for cleaning purposes, are estimated to be a $50 billion industry worldwide. However, the use of detergents has been found to have a significant impact on marine life.

The following bullet points highlight some of the adverse effects of detergent usage:

- Detergents can cause an increase in foam production in water bodies, which can lead to a decrease in oxygen levels and the death of aquatic animals.

- The surfactants present in detergents can affect the surface tension of water, making it difficult for fish to breathe and absorb nutrients.

- Some chemicals present in detergents like phosphates, nitrogen and potassium can cause eutrophication or excessive growth of algae. This can reduce light penetration into water bodies leading to decreased photosynthesis by aquatic plants.

- Detergent pollution can also lead to bioaccumulation of toxins in fish which may then be passed onto humans who consume them.

Therefore, it is essential for manufacturers and consumers alike to consider alternative options that are eco-friendly and biodegradable when using detergents.

Paper Production

Paper production is a significant industry with a global demand for paper products that continues to increase year after year. However, this growth in demand has resulted in sustainability challenges due to the use of virgin pulp and the depletion of natural resources.

Recycling options have been developed to address these challenges by reducing the amount of waste generated and conserving energy and resources. This involves collecting, sorting, and processing used paper products into new raw materials for paper production.

While recycling has become an essential part of sustainable paper production practices, it still faces challenges such as contamination from non-paper materials, limited market demand for recycled materials, and increased energy consumption during the recycling process.

Despite these challenges, recycling remains a critical solution towards achieving sustainable and environmentally friendly paper production.

Textiles

The fashion industry, with its ever-changing trends and fast fashion culture, is a behemoth that has a significant impact on the environment.

Textiles manufacturing contributes to this impact through high water consumption, chemical pollution, and carbon emissions.

As such, sustainability practices have become increasingly important in the industry.

Manufacturers are implementing eco-friendly materials like organic cotton or recycled polyester, reducing waste by making use of leftover fabrics or creating closed-loop production systems that recycle water and chemicals.

Brands are also engaging in transparency initiatives to disclose their supply chain information and promote ethical labor practices.

Despite these efforts, there is still much work to be done in improving the overall sustainability of textiles manufacturing in order to reduce its environmental impact.

Glass

Glass is a versatile and durable material that can be molded into various shapes and sizes, making it an ideal choice for architecture, packaging, and household items. Glass manufacturing involves melting raw materials such as sand or silica at high temperatures to form a molten liquid that can then be shaped into different forms. The properties of glass include its transparency, hardness, and resistance to chemical attack. One important aspect of glass production is the addition of small amounts of other elements such as sodium or calcium to modify its properties. For example, adding sodium oxide can make the glass more resistant to breakage while adding calcium oxide can increase its strength. Overall, the precise control over the composition and processing of glass allows for a wide range of unique products with varying properties to be created for different applications.

Pharmaceuticals

Pharmaceuticals are intricate compounds synthesized through a controlled series of chemical reactions that form complex molecular structures. The development and production of these drugs must adhere to strict pharmaceutical regulations to ensure safety, efficacy, and quality.

Drug development involves several stages, including preclinical testing, clinical trials, regulatory approval, and post-market surveillance. The process requires collaboration between scientists, clinicians, regulators, and other stakeholders to bring new medicines to market.

Despite the rigorous standards for drug development and manufacturing, challenges remain in ensuring access to affordable medications worldwide. Efforts are underway to address these issues through policies aimed at promoting innovation while balancing affordability and patient access to essential medicines.

Production Methods for Sodium Sulfate

One common method for producing sodium sulfate involves the reaction of sodium hydroxide with sulfuric acid. This process is known as the Mannheim process and it has been used since the 19th century to produce large quantities of sodium sulfate.

In this process, sulfuric acid reacts with sodium chloride or sodium carbonate to form sodium sulfate and hydrogen chloride or carbon dioxide gas. However, this method has several drawbacks such as low production efficiency, high energy consumption, and limited raw material sources.

To overcome these issues, alternative methods such as the Hargreaves process have been developed which involve using cheaper raw materials and have higher production efficiency. Overall, the choice of production method depends on various factors including cost-effectiveness, environmental impact, and availability of raw materials.

Read also: What Is The Name Given To The Group 0 Elements

Importance of Sodium Sulfate in Agriculture

In modern agriculture, sodium sulfate plays a crucial role as a fertilizer and soil conditioner. It is used to improve soil structure, increase water retention capacity, and enhance plant growth.

Sodium sulfate provides plants with essential nutrients such as sulfur and magnesium, which are necessary for chlorophyll synthesis and protein formation. However, the excessive use of sodium sulfate can lead to salinization of the soil, making it unsuitable for crop growth. In addition, some crops may be sensitive to high levels of sodium in the soil.

Farmers must consider these limitations when using sodium sulfate as a fertilizer or soil conditioner. There are alternative fertilizers available that can provide similar benefits without the adverse effects of salinization or high levels of sodium in the soil.

Overall, while sodium sulfate has its benefits in agriculture, farmers need to be cautious about its use and explore other alternatives for optimal crop growth.

Environmental Impact of Sodium Sulfate

The production of sodium sulfate generates approximately 2.6 million tons of waste each year, according to a report by the United Nations Environment Programme. The environmental impact of this waste can be significant, as it can lead to pollution and contamination of water sources if not properly managed. Recycling strategies for sodium sulfate are being developed to help reduce waste and limit its negative effects on the environment. One approach involves using the waste material as a raw material for other industries, such as glass or cement manufacturing. Another strategy is to incorporate technologies like wastewater treatment that can extract valuable resources from the waste material while minimizing its detrimental effects on natural resources and ecosystems. While these approaches require investment in infrastructure and technology, they have the potential to promote sustainable development by reducing reliance on virgin materials and minimizing environmental harm caused by industrial processes.

Comparison with Other Salts

After discussing the environmental impact of sodium sulfate, it is important to compare it with other common salts and explore possible alternatives.

Sodium sulfate is widely used in various industries such as detergents, textiles, and glass manufacturing due to its low cost and availability.

However, there are several other salts that can replace sodium sulfate in these applications.

For example, magnesium sulfate has similar properties but is more environmentally friendly since it occurs naturally and does not require energy-intensive production processes.

Similarly, sodium chloride (table salt) can be an alternative for some applications where the presence of sulfates is not necessary.

Therefore, depending on the specific use case, using different salts or exploring new alternatives might reduce the overall environmental impact of industrial processes while maintaining their efficiency and effectiveness.

Safety Precautions

Handling and storage guidelines, health hazards, and environmental hazards are important safety precautions to consider when working with sodium hydroxide.

It is crucial to handle the chemical with care, wearing appropriate personal protective equipment such as gloves and goggles.

Sodium hydroxide can cause severe burns if it comes into contact with skin or eyes, and inhalation of its fumes can result in respiratory irritation.

Additionally, the chemical can be harmful to the environment if not disposed of properly.

Handling and Storage Guidelines

To ensure safe storage and handling, it is recommended to follow the guidelines provided for managing sodium hydroxide and sulfuric acid. These guidelines include:

- Proper storage – Sodium hydroxide should be stored in a cool, dry place away from moisture, heat, and incompatible substances such as acids. Sulfuric acid should be stored in a cool, dry area away from sources of ignition and incompatible materials such as organic compounds.

- Spill containment – Sodium hydroxide and sulfuric acid are both highly corrosive substances that can cause serious damage if spilled or released into the environment. Therefore, it is important to have spill containment measures in place such as absorbent materials or chemical neutralizers.

- Handling precautions – Always wear appropriate personal protective equipment (PPE) when handling these chemicals including gloves, safety glasses, and lab coats. Avoid direct contact with skin or eyes and ensure proper ventilation when working with these substances.

- Disposal regulations – Proper disposal of sodium hydroxide and sulfuric acid is essential to prevent environmental contamination. Follow all local regulations for disposal methods including neutralization or treatment before disposal.

By following these guidelines for proper storage, spill containment, handling precautions, and disposal regulations you can ensure your safety while working with sodium hydroxide and sulfuric acid.

Health Hazards

In order to handle and store sodium hydroxide and sulfuric acid safely, it is important to understand the potential health hazards associated with these chemicals.

When sodium hydroxide reacts with sulfuric acid, a salt known as sodium sulfate is produced. However, this reaction can also produce toxic fumes and may cause skin irritation or burns if not handled properly.

To prevent harm from exposure to these chemicals, it is important to follow proper safety protocols such as wearing protective clothing and gloves, using ventilation systems in enclosed areas, and storing the chemicals in appropriate containers.

In addition, toxicology studies have been conducted to determine the effects of exposure on human health and provide insight into prevention measures that should be taken.

By taking these precautions and utilizing the information provided by toxicology studies, individuals can minimize their risk of harm when handling or storing sodium hydroxide and sulfuric acid.

Environmental Hazards

The potential environmental hazards associated with the reaction between sodium hydroxide and sulfuric acid must be carefully considered before carrying out any procedures, as this chemical reaction can release harmful substances into the air and water, potentially causing damage to ecosystems and wildlife.

Environmental regulations have been put in place to prevent such harm from occurring, but it is still important to take necessary precautions when handling these chemicals.

The impact on ecosystems from this reaction can range from altering pH levels in water sources to disrupting natural habitats for wildlife.

It is crucial for individuals and industries alike to prioritize environmentally responsible practices when using sodium hydroxide and sulfuric acid in order to mitigate their impact on the environment.

Further Research and Development

The subtopic of further research and development in chemical reactions is a critical area of study for both industry and the environment. Understanding the summary of key points regarding chemical reactions can help to improve safety measures, increase efficiency, and reduce waste production.

As industries continue to advance and environmental concerns become more pressing, the implications of future developments in this field are extensive and far-reaching. A clear comprehension of these complex processes will be essential for addressing issues such as pollution prevention, energy conservation, and sustainable manufacturing practices.

Summary of Key Points

Imparting knowledge on the chemical reaction between sodium hydroxide and sulfuric acid, the salt produced is a neutralization product known as sodium sulfate.

This reaction involves the exchange of ions between the two reactants, leading to the formation of water and sodium sulfate.

Understanding this chemical reaction is crucial for various industries that rely on it for producing other chemicals or products.

Furthermore, future implications for industry and the environment may arise from this understanding, including finding ways to reduce waste and improve efficiency in production processes while minimizing environmental impact.

Thus, further research and development into this area can lead to significant advancements in both industry and sustainability efforts alike.

Importance of Understanding Chemical Reactions

Understanding chemical reactions is like peeling back the layers of an onion, revealing the intricate processes that drive industry and sustainability efforts forward. Chemical reactions are fundamental to our daily lives and have a significant impact on various industries such as pharmaceuticals, agriculture, and energy production.

Education about chemical reactions and their importance is crucial in understanding the implications of these processes in everyday life. It enables us to make informed decisions about products we use, impacts on the environment, and potential health risks associated with exposure to chemicals.

Furthermore, knowledge of chemical reactions can facilitate innovation in developing new materials, improving existing technologies and discovering alternative energy sources. Therefore, education about chemical reactions plays a vital role in shaping our future by promoting sustainability and enabling scientific advancements that benefit society.

Future Implications for Industry and the Environment

Exploring the potential consequences of chemical reactions on industry and the environment is essential in developing sustainable practices for future generations. The impacts of chemical reactions can be far-reaching, affecting not only human health but also ecosystems and economies.

In terms of regulation, industries must adhere to strict guidelines to ensure their processes do not harm the environment or public health. Failure to comply with these regulations can result in hefty fines and legal action.

However, there are alternative production methods being developed that aim to minimize negative environmental impacts while maintaining efficiency and cost-effectiveness. These methods include using renewable energy sources, utilizing waste materials as feedstocks, and implementing closed-loop systems that reduce waste generation.

As we continue to advance technologically, it’s critical that we prioritize sustainability in our industrial practices to mitigate negative effects on both industry and the environment.

Frequently Asked Questions

What is the chemical equation for the reaction between sodium hydroxide and sulfuric acid?

This reaction between sodium hydroxide and sulfuric acid is an exothermic neutralization process. The balanced equation for the reaction mechanism is 2NaOH + H2SO4 -> Na2SO4 + 2H2O.

What are the physical characteristics of the salt produced?

The salt produced when sodium hydroxide reacts with sulfuric acid is sodium sulfate. It has a crystalline structure and high solubility in water. Sodium sulfate finds applications in the manufacture of detergents, paper, and glass industries due to its ability to lower melting points and increase fluidity.

How does the production of sodium sulfate differ from the production of other salts?

The production of sodium sulfate differs from other salts due to its wide range of industrial applications and significant economic impact. It is commonly produced through the reaction between sodium hydroxide and sulfuric acid, resulting in a white crystalline solid with various physical characteristics.

What are some potential environmental hazards associated with the industrial applications of sodium sulfate?

Industrial applications of sodium sulfate may lead to environmental hazards such as soil and water pollution. Potential solutions include using alternative processes or implementing regulatory measures to control waste disposal and emissions.

Are there any alternative methods for producing sodium sulfate that may be more sustainable or efficient?

Sustainable methods and efficiency improvements for producing sodium sulfate include using waste materials such as gypsum, reducing energy consumption through process optimization, and employing renewable energy sources. These alternatives aim to reduce environmental impact while maintaining production levels.

Conclusion

The reaction between sodium hydroxide and sulfuric acid results in the production of sodium sulfate, a white crystalline solid that is commonly used in various industrial applications. This salt possesses several unique properties, including its ability to act as a drying agent and a laxative.

The production of sodium sulfate involves several methods, including the use of natural resources and chemical synthesis. Sodium sulfate has significant importance in agriculture, where it is used as a fertilizer to improve crop yields.

However, the environmental impact of this salt must also be considered, particularly regarding its potential toxicity to aquatic life when introduced into water systems. In conclusion, sodium sulfate’s role as an essential industrial salt cannot be overstated.

As research continues to explore its uses and effects on our environment and industries, it remains crucial for us to consider ways to minimize its negative impact while maximizing its benefits. With careful consideration and implementation of safety precautions, we can continue utilizing this vital salt while minimizing any adverse effects on our planet and society as a whole.